Welcome to the official website of Hebei Ruihua Metallurgical Technology Co., Ltd.!

Welcome to the official website of Hebei Ruihua Metallurgical Technology Co., Ltd.!

Composition of Refractory Materials in the Slide Plate Slag Retention System

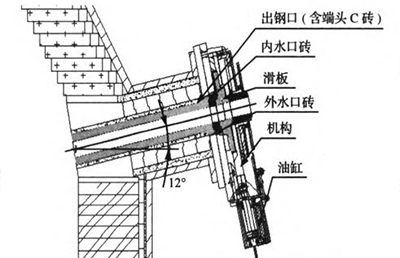

Using slide plates to prevent slag in converter tapping is one of the most advanced methods internationally, yet also the most challenging slag prevention technology. The refractory material in this converter slide plate slag retention system primarily consists of five refractory components: the taphole brick, inner nozzle brick, upper slide plate, lower slide plate, and outer nozzle brick. The converter slide plate is one of the most critical components in this technology. The taphole, inner nozzle, slide plate brick, and inner hole of the outer nozzle brick form the tapping channel, while the slag retention function is achieved through the movement and opening of the lower slide plate. The refractory structure of a conventional slide plate slag retention system is shown in Figure 1.

Main Problems with Refractory Application

Domestic converter slag retaining technology is still in its infancy. The relevant refractory materials, equipment, and replacement techniques require continuous improvement and optimization. The main refractory issues and shortcomings currently hindering the development of this technology include the following.

2.1 Relatively Short Slide Plate Life

Currently, aluminum-zirconium-carbon is the material of choice for converter slide plates in China. As a ladle slide plate material, it offers high strength, excellent thermal shock resistance, and excellent erosion and corrosion resistance. However, for converter slide plate slag retaining technology, the slide plate life is relatively short, only stable at 10 to 14 furnaces, or roughly once per shift. This relatively frequent mechanism replacement makes it unsuitable for the fast-paced converter steelmaking process and increases worker workload.

2.2 Taphole Life Needs Further Improvement

Taphole life is a key indicator of converter slide plate slag retaining technology. Frequent exposure to direct erosion and intense erosion from high-temperature molten steel and highly oxidizing slag, coupled with rapid cooling and heating, makes the taphole extremely susceptible to damage. Its service life directly impacts the converter’s smelting cycle, steelmaking productivity, and slag retention, ultimately affecting steel quality. The integrity of the taphole directly controls the amount of slag discharged from the converter, and has a direct impact on alloy yield and subsequent refining processes (LF, RH, etc.).

Currently, its service life is stable at 90 to 110 furnaces, but achieving a longer service life is difficult. The core issue lies in the fact that the taphole and the inner nozzle bricks are bonded together using a flat surface or a splice-and-joint structure bonded by fireclay. This contact area is in surface-to-surface contact, which increases the chance of air infiltration during use. Frequent replacements can lead to oxidation, loosening, and flaking of the contact surface. This is particularly true at the taphole-inner nozzle contact point (end C brick), where multiple sets of inner nozzle bricks are used. Therefore, the service life of the taphole end C brick has become a key factor in determining the longevity of the taphole.

Measures to Improve Refractory Application Issues

3.1 Improving and Optimizing the Material and Structure of Slide Plates to Significantly Increase Service Life

To address the common issues with converter slide plate materials, our company, based on the actual production conditions of steel mills, has continuously optimized slide plate materials, improving their comprehensive properties such as oxidation resistance, wear resistance, thermal shock stability, and corrosion resistance. We have developed materials such as magnesium-carbon, aluminum-carbon, aluminum-zirconium-carbon, and aluminum-zirconium-carbon inlaid with zirconium. Ultimately, we adopted aluminum-zirconium-carbon composites with zirconium inlaid rings. This significantly increased the overall service life of the slide plates, steadily increasing the average service life from 10-16 furnaces to 23-25 furnaces, with a maximum service life of 27 furnaces, a leading level in China (see Table 1 for specific data). This has achieved the goal of replacing the slide plates only once per steel mill, significantly reducing worker workload and providing a strong foundation for the implementation of the steel mill’s fast-paced converter steelmaking process.

3.2 Measures to Improve the Overall Lifespan of the Taphole

During the converter tapping process, molten steel flows through the taphole into the ladle. Under the impact of the high-temperature molten steel, the taphole’s refractory material gradually melts away, causing the taphole’s inner hole to expand into an “inverted trumpet” shape (smaller at the top and larger at the bottom). Because the taphole is assembled from a single shell brick and end bricks (C bricks), the C bricks cannot be replaced individually during actual use. After 90-110 furnaces, even if the inner nozzle bricks are replaced, the “expansion” of the C bricks will be so large that they no longer securely bond with the inner nozzle bricks, posing a high risk of steel leakage at the interface. In this case, the entire taphole must be replaced immediately, while the remaining shell bricks in the converter ladle wall can continue to be used. This significantly reduces the overall lifespan of the taphole, increasing the frequency of replacements and impacting production organization and capacity utilization, while also increasing the cost of the taphole’s refractory materials. The new design replaces the monolithic C-brick structure with a modular one, employing individually replaceable replacement bodies (bowl bricks) in the “hole expansion area.” With the new taphole C-brick structure, when the “hole expansion” of the taphole C-brick is so large that it cannot ensure a safe bonding area with the inner nozzle bricks, a bowl brick assembly of individually replaceable taphole C-bricks is used. This ensures a safe bonding area between the taphole C-bricks and the inner nozzle bricks, and achieves a continuous increase in the taphole lifespan by 20% to 40%. This effectively increases the online service life of the taphole from approximately 90 to 110 furnaces to 120 to 140 furnaces, and significantly improves the safety factor for steel casting in this area. The detailed design of the taphole C-brick is shown in Figure 2.

Conclusion

1) Through continuous innovation in key converter slag-blocking slide technologies, our slide-type slag-blocking technology has continuously strengthened its competitiveness in both domestic and international markets. It has successfully entered the key application market for slag-blocking technology in large and medium-sized converters with a capacity of over 200 tons, including Germany’s SLAZGITTER.AG and Shougang (Qian’an). The technology has proven effective, with tapping times consistently maintained at 6-8 minutes and an average service life exceeding 23 furnaces, with a maximum lifespan of 27 furnaces, placing it at the forefront domestically.

2) The structural design of the C-brick at the junction of the taphole and the inner nozzle bricks has been optimized. The C-brick at the taphole end has been changed from a single, integral design to a combination of replaceable bowl bricks. This effectively increases the service life of the taphole from approximately 90-110 furnaces to 120-140 furnaces. This reduces the frequency of taphole replacements and labor intensity, significantly improves the safety factor for pouring steel in this area, reduces slag discharge, and reduces the overall consumption of refractory materials in steelmaking.

Previous Article:No more articles

Next article:What are the main parameters of the converter?