Welcome to the official website of Hebei Ruihua Metallurgical Technology Co., Ltd.!

Welcome to the official website of Hebei Ruihua Metallurgical Technology Co., Ltd.!

C-Generation Electric Furnace – Electric Furnace Opening and Closing Mechanism

Official Release in 2022

Electric Furnace Slag-Free Steelmaking

Leading the Way in Molten Steel Flow Control Technology

Quality, Service, Innovation

…

Pre-sales for New Products Now Open!

The first eccentric-bottom-tapped electric arc furnace was manufactured in Germany in 1983, and steelmaking began using this method for the first time in 1987. Traditionally, the tapping port of an electric furnace is located above the molten pool at the rear of the furnace. During tapping, the furnace tilts, causing slag to flow out of the trough and into the ladle in a parabolic arc. To ensure complete removal of the slag, the furnace must tilt at an angle of 42-45 degrees. This tapping method results in severe slag contamination, hindering off-furnace refining of the molten steel. Furthermore, the long and dispersed steel stream during tapping results in significant aspiration and a significant temperature drop. Market demand has led to the development of slag-blocking methods using eccentric-bottom tapping, making slag-free tapping a trend. To improve steel purity, it is crucial to minimize contamination of the molten steel at each process step before it enters the mold, and to minimize the removal of inclusions from the molten steel. To achieve this, the following measures should be implemented:

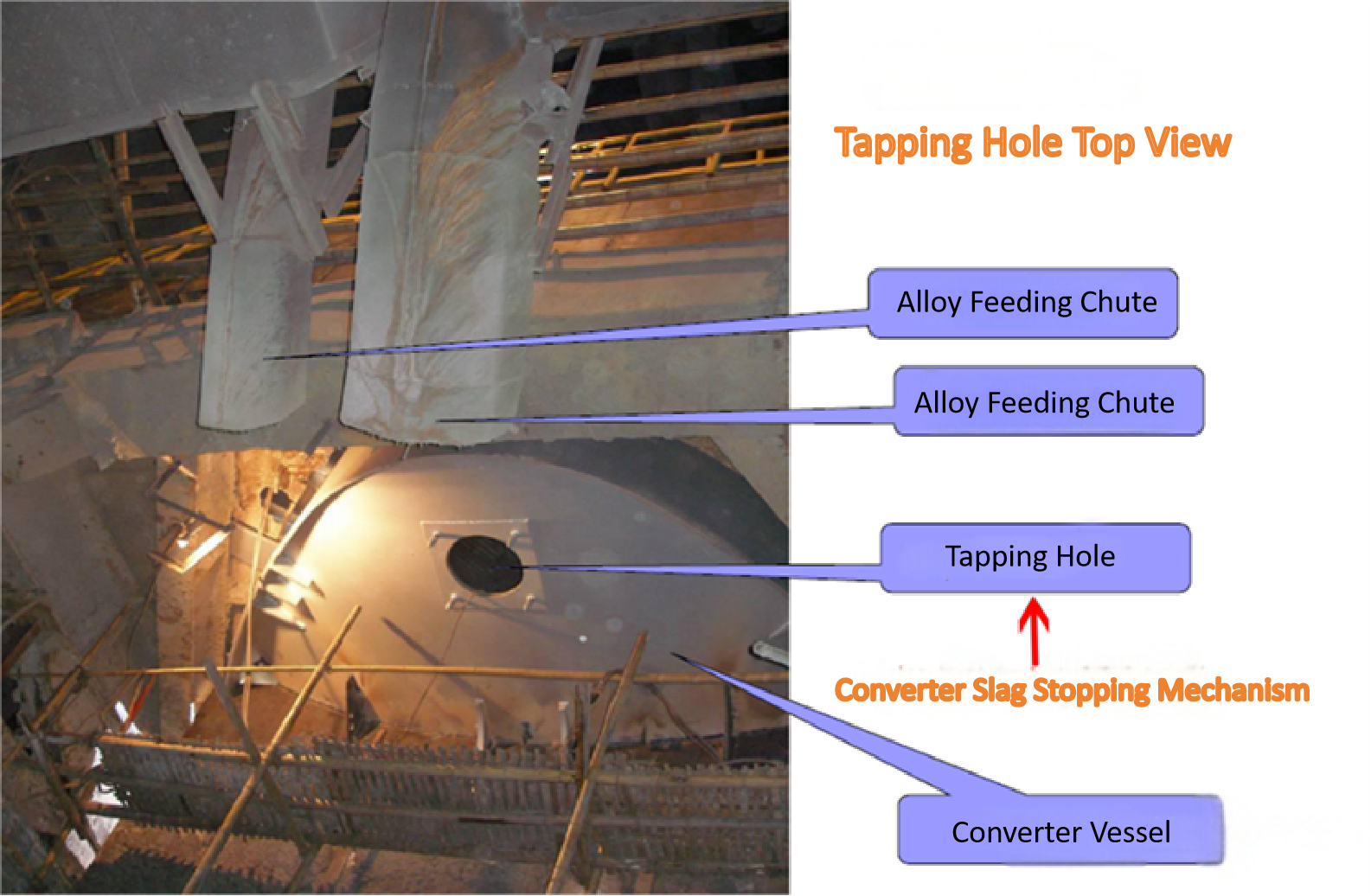

a. Slag-free tapping: Electric furnaces use eccentric-bottom tapping to prevent slag from entering the ladle. In response to market demand, Hebei Ruihua Metallurgical Technology Co., Ltd. has designed a slag-blocking sliding nozzle mechanism on the eccentric bottom tapping port of an electric furnace to achieve slag-free tapping. The operating diagram of the mechanism is as follows:

b. Select appropriate refining treatment methods based on the steel grade’s requirements to purify the molten steel and improve inclusion morphology.

c. Utilize electromagnetic stirring technology and install electromagnetic brakes to control the flow of the injection stream. This promotes the floating of inclusions, improving the purity of the molten steel, and so on.

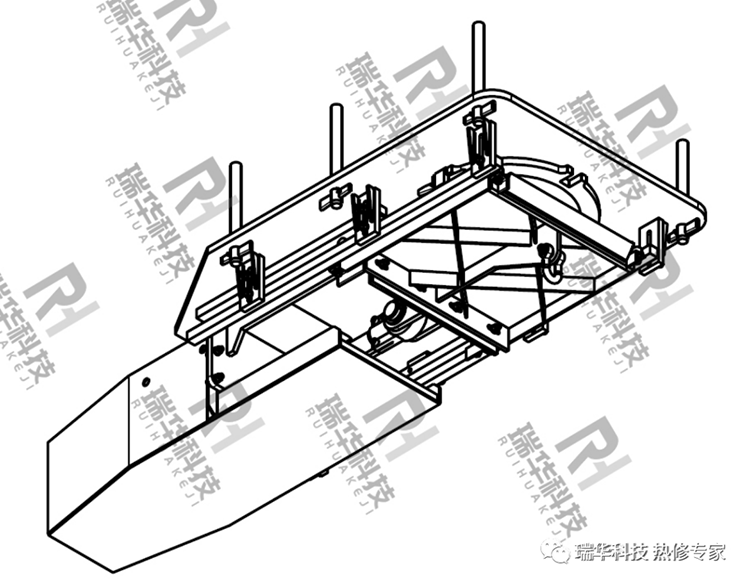

This article focuses on the eccentric bottom tapping mechanism for electric furnaces, designed by Hebei Ruihua Metallurgical Technology Co., Ltd. The key structural principle is that this device consists of a fixed portion, a frame, bearings, a drive, and a cylinder. The cylinder drives the reciprocating motion of the bearings in the frame, achieving slag-free tapping and slag-flowing operation.

The electric furnace slag-blocking sliding nozzle mechanism is externally installed at the end of the furnace’s tapping port. Six connecting shafts must be welded to the furnace bottom. First, secure the center of the tapping port to the fixed portion with a wedge. Next, install the frame. Adjust the vertical distance between the bearing rails according to the drawing requirements and tighten with bolts. Install the frame and cylinder, bolting the two together. The entire mechanism is then mounted on the pre-welded connecting shafts and tightened with wedges. Finally, connect the cylinder gas source to the cylinder, start the cylinder, and drive the frame to reciprocate. If operation is smooth, install the cylinder protective plate and set aside. The entire installation takes less than 10 minutes and does not affect furnace smelting.

This equipment features the following:

This equipment’s advantages lie in achieving slag-free tapping and increasing the usable area of the water-cooled furnace wall. During tapping, the device tilts approximately 5° to the tapping side, then opens the mechanism. The tapping port filler automatically drops under the static pressure of the molten steel, allowing molten steel to flow into the ladle, enabling automatic pouring and tapping. When the required molten steel reaches approximately 95% of the required volume, the device quickly tilts back to prevent slag. During this tilting process, approximately 5% of the molten steel and a small amount of slag still flow into the ladle. After the furnace is properly tilted (remaining 10%-15% steel and ≥95% slag), the tapping port is inspected and maintained, the tapping port is closed, the filler is added, scrap is loaded, and arc melting is resumed.