Welcome to the official website of Hebei Ruihua Metallurgical Technology Co., Ltd.!

Welcome to the official website of Hebei Ruihua Metallurgical Technology Co., Ltd.!

Product quality is the foundation of an enterprise’s survival and one of the important indicators to measure the quality of an enterprise’s products. If an enterprise wants to gain a firm foothold in the fierce market competition, it must practice internal skills and strengthen quality management of the production process. For Ruihua’s overall operation, “strictly control the production process and ensure product quality. No matter how strict it is, it is not excessive, and no matter how careful it is, it is not redundant.” Always put product quality first. The good use of products and customer satisfaction are the goals pursued by the enterprise. Adherence to excellent product quality is the magic weapon for the enterprise to defeat the enemy and win in the fierce competition.

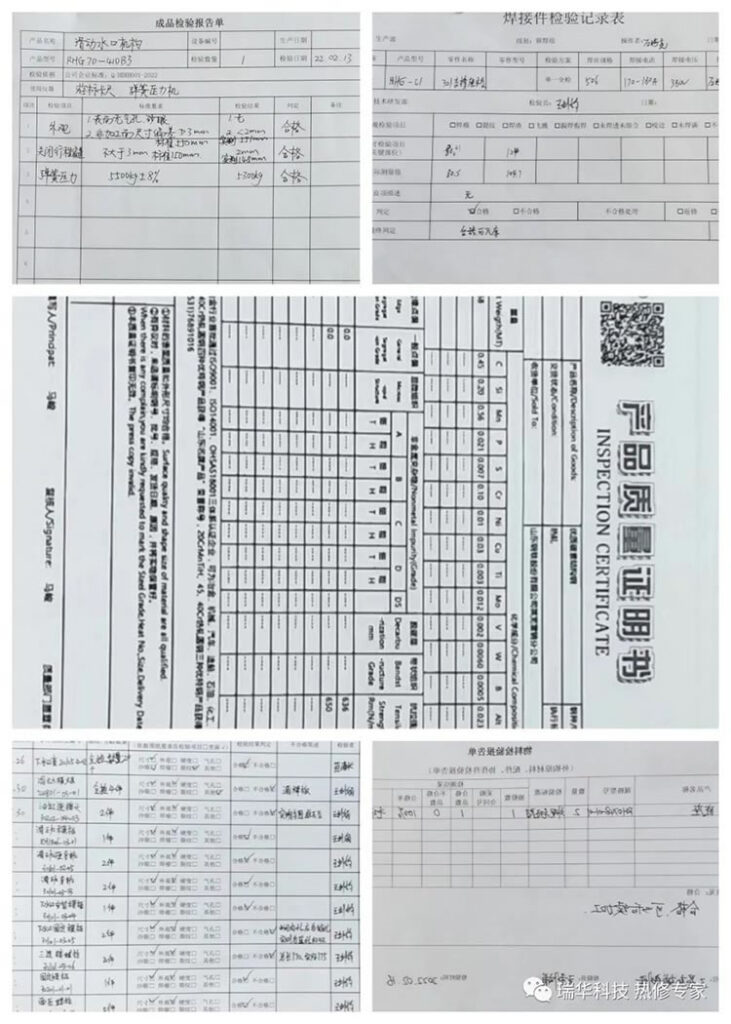

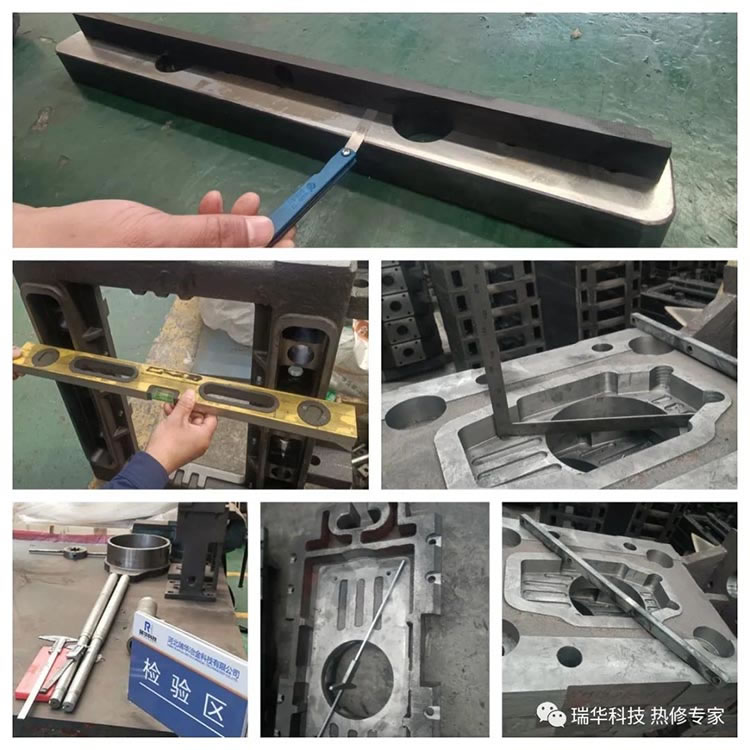

Inspection of raw material castings, inspection of product raw materials and other related parts according to drawing requirements.

Hardness testing to ensure that the material strength meets the drawing requirements

Process inspection – Carry out self-inspection and special inspection on the first product in a timely manner to find problems in time and reduce the production of defective products in the process.

Summarize the quality problems that occur during normal production, organize employee training, and discuss with employees the causes of quality problems. Because employees are often on the production line, they have the best understanding of the production process of the product, so employees are most clear about where some problems lie. Taking employees’ suggestions will greatly help improve product quality, so that product quality can truly achieve the effect of continuous improvement, while improving product quality. It will also improve employees’ sense of responsibility and quality awareness, and truly enable employees to participate in quality management.

Finished product inspection—for quality inspectors, our work is repetitive, tedious, and rigorous. To ensure every parameter of every batch of spare parts meets the highest standards, we must be rigorous and meticulous. “Only by working with dedication can we get things done well. We must always ingrain and translate customer quality expectations into action.”

The purpose of assembly and commissioning inspection is to verify the interchangeability between complete sets of spare parts and ensure that the product can be used smoothly at the customer’s site.

Elastic component testing – Before the production of special order products, front-line employees are trained to let them know the product details and control points that should be paid attention to during the production process. Employees are made aware of the high quality requirements of this product, which will attract their attention and thus improve their quality awareness.

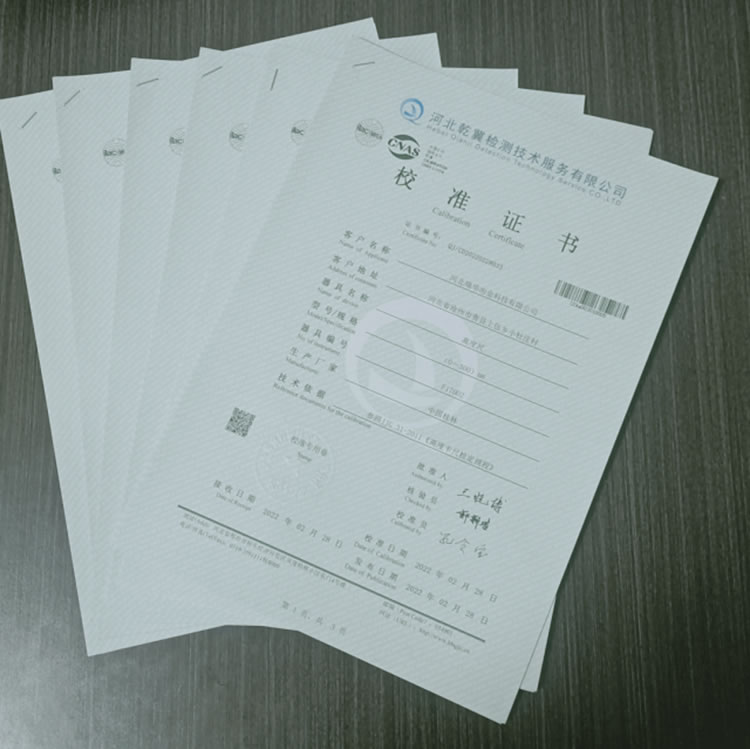

Testing equipment is sent to metrology and testing agencies for appraisal to ensure the accuracy of measuring tools and instill the “zero defect” quality awareness into the blood of every employee.

We all know that product quality is determined by each of our employees, not by quality inspectors! Therefore, improving product quality requires the joint efforts and participation of every employee. Employees should observe more, reflect more diligently, actively learn operational skills, and improve their own quality. Strengthening production process control at every step is our primary control method. By ensuring strict control at every level, we can reduce the number of defective products, thereby improving product quality, reducing process waste, and enhancing product competitiveness.

*** management, full participation, full control, strive to create a brand

For any brand or famous brand to gain public favor, the most fundamental factor is quality. Good, reliable, and stable quality is the cornerstone of a product. Every employee must regard responsibility as a mountain, with the product in their hands and quality in their hearts. They must strive for detail and be sincere in every process. We must integrate the idea that quality is the lifeblood of the company into our work with our minds and hearts. In our work, we must be more careful and less casual, more responsible and less evasive, and continuously improve the quality of our work and our sense of responsibility to ensure effective improvement in product quality. At the same time, quality also represents the bottom line of the company’s reputation. To maintain this bottom line, all Ruihua employees are taking action!

Previous Article:Sliding gate installation specification operation

Next article:Features of RHG-B4 ladle sliding gate mechanism