Welcome to the official website of Hebei Ruihua Metallurgical Technology Co., Ltd.!

Welcome to the official website of Hebei Ruihua Metallurgical Technology Co., Ltd.!

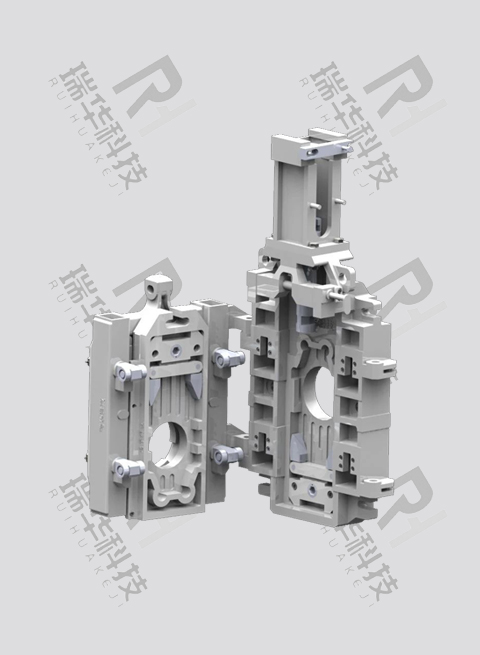

With the development of rapid, efficient continuous casting and secondary refining technologies and processes, the sliding nozzle (SN) system has become increasingly important in modern steelmaking, becoming an indispensable component. It is a control device for molten steel during the continuous casting process, precisely regulating the flow of water from the ladle to the tundish, achieving a balance between inflow and outflow, thus facilitating the controlled continuous casting operation. The sliding nozzle system has rapidly developed due to its excellent controllability and its ability to improve steelmaking production efficiency. Today, sliding nozzle systems are widely used in ladles and tundishes both domestically and internationally.

A sliding nozzle controls the steel flow by adjusting the relative displacement of two perforated refractory bricks, connected and assembled together via a sliding mechanism installed at the bottom of the ladle. The upper nozzle and upper slide are fixed in the mechanism, while the lower slide and lower nozzle are mounted on the carriage and can move left and right. When the inner holes of the upper and lower slides overlap, the nozzle opening is maximized; when they do not, the nozzle closes. The sliding nozzle carriage is moved left and right by a hydraulic cylinder, and the lower and upper slides are spring-loaded to prevent gaps between the slides during movement, thus preventing steel leakage. The advantages of a sliding nozzle include improved working conditions, faster ladle turnover, reduced refractory material consumption, reduced steel leakage, improved molten steel quality, and facilitated refining outside the furnace.