Welcome to the official website of Hebei Ruihua Metallurgical Technology Co., Ltd.!

Welcome to the official website of Hebei Ruihua Metallurgical Technology Co., Ltd.!

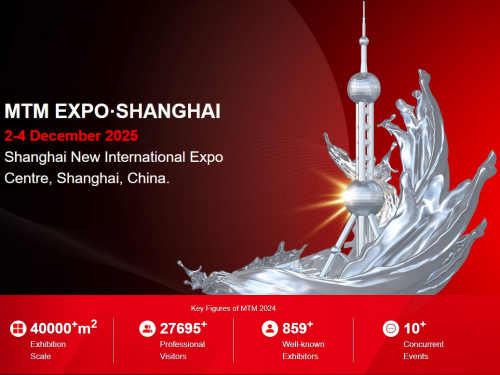

2025-12-8

2025-11-6

2025-8-26

2025-6-6

2025-6-6

2025-6-6

2025-6-6

2024-12-20

2024-10-12

2024-8-16